Under Construction

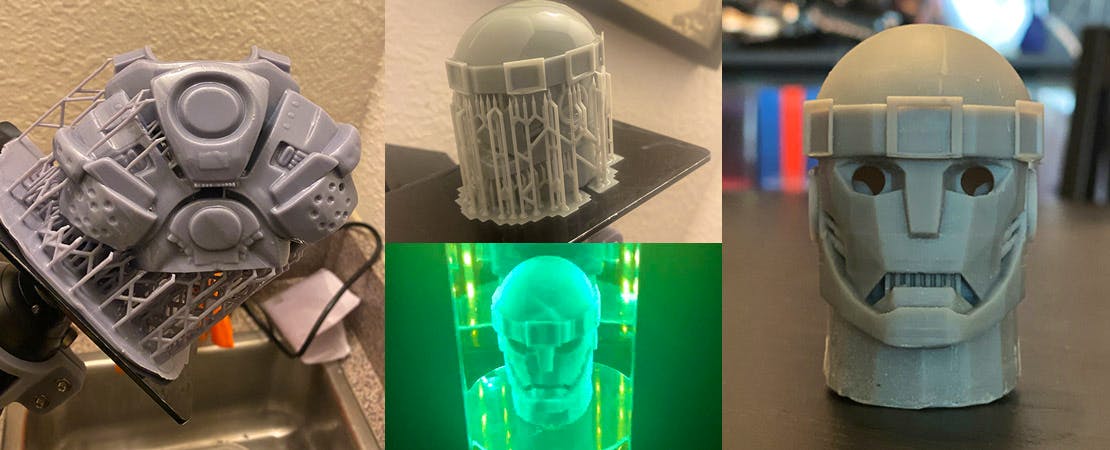

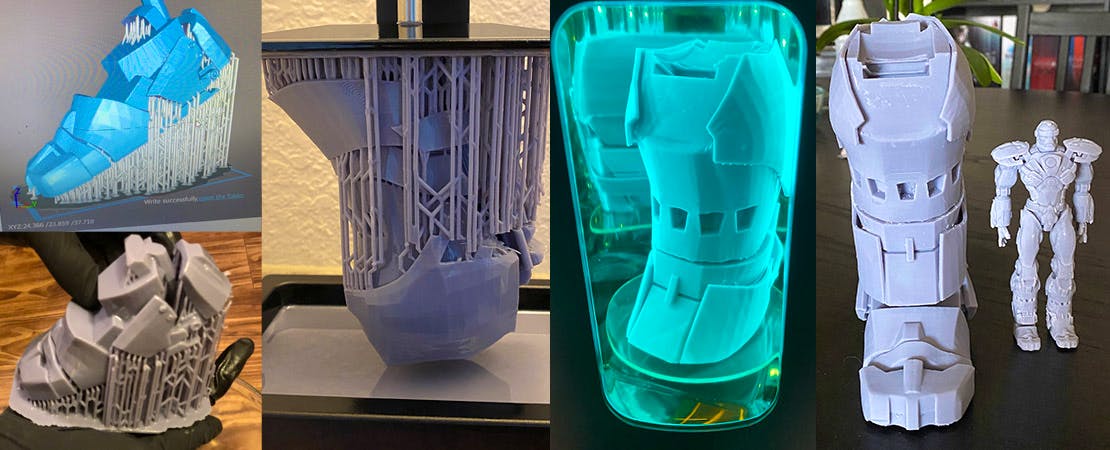

The Sentinel project was the most insane and over-ambitious personal projects of my life. Besides the initial 3D Modeling, every single aspect of the project was a first-time experience for me. I cannot wait to share the story of my process, successes, and failures. For now, I am focusing on the core content of my portfolio and creative technology sections to get my website launched. Since you took the time to stop by, I wanted to give you a glimpse at what the 3D printing process looked like while building this massive project on such a tiny printer, the Elegoo Mars.

3D RESIN Printing

The Elegoo Mars has a build volume of 4.7" x 2.6" x 6.1" (120 x 68 x 155mm). Each piece maxed out the build plate except for the arms, head, and crotch. Printing with resin is a process, but the UV screen which hardens the photopolymer resin is 4k meaning, you can get very high-quality finishes. The process also includes trimming supports, carefully cleaning excess resin using a combination of water, 90% isopropyl alcohol, or acetone. Once cleaned and dried, the part must be placed in a UV lamp for final curing; the sun also works, but depending on the time of year, your location, and the weather forecast, it certainly isn't the most efficient method. Once the piece is cured, any remaining supports must be filed, and connectors must be sanded to fit their respective counter-part.